| Dimensions (W x D x H) | 1070 mm x 880 mm x 695 mm (one unit) /1070 mm x 880 mm x 1850 mm (three units) |

|---|---|

| Maximum working height | 290 mm (one unit) |

| Number of batches | 7680 per unit |

| Volume | 21 l per unit |

| Maximum load | 55 kg per unit |

| Maximum expansion | Stackable up to 3 units |

| Rotation speed | 20–400 min-1 (3mm: 1'000 min-1) depending on load and stacking |

| Shaking throw | 3 mm / 25 mm / 50 mm / adjustable |

| Temperature | Without cooling max. 10 °C above AT to 65 °C; Minimum temperature from 4 °C depending on cooling system |

| Standard parameters | Temperature, rotation speed, timer |

| Optional parameters | Cooling, humidity, CO2 |

| Ambient humidity (rH) | Up to 85 % non-condensing |

| Power supply | 115/230 V ± 10%, 50/60 Hz |

| Interface | Ethernet |

Data Sheets

Flyer & Brochures

Scientific Poster

Thank you for your interest!

Please enter your e-mail address in order to download the document.

Thank you for your interest!

Please enter your e-mail address in order to download the document.

Application Notes

Manuals

Thank you for your interest!

Please enter your e-mail address in order to download the document.

Thank you for your interest!

Please enter your e-mail address in order to download the document.

Thank you for your interest!

Please enter your e-mail address in order to download the document.

Thank you for your interest!

Please enter your e-mail address in order to download the document.

Thank you for your interest!

Please enter your e-mail address in order to download the document.

Thank you for your interest!

Please enter your e-mail address in order to download the document.

Thank you for your interest!

Please enter your e-mail address in order to download the document.

Thank you for your interest!

Please enter your e-mail address in order to download the document.

| Multitron | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Dimensions (W x D x H) | 1070 mm x 880 mm x 695 mm (one unit) /1070 mm x 880 mm x 1850 mm (three units) | 800 mm x 625 mm x 700 mm (one unit) / 800 x 625 x 1490 mm (two units) | 1070 × 880 × 550 mm (single unit without cooling) | 800 mm x 625 mm x 700 mm (one unit) / 800 x 625 x 1490 mm (two units) | 1070 × 880 × 550 mm (single unit without cooling) | 450 mm x 380 mm x 90 mm | ||||||||

| Maximum working height | 290 mm (one unit) | 173 mm (one unit) / 960 mm (two units) | 1300 mm (three units) | 173 mm (one unit) / 960 mm (two units) | 1300 mm (three units) | |||||||||

| Number of batches | 7680 per unit | 105 per unit | 197 per unit | 105 per unit | 197 per unit | 49 | ||||||||

| Volume | 21 l per unit | 9 L per unit | 21 L per unit | 9 L per unit | 21 L per unit | 3 L | ||||||||

| Maximum load | 55 kg per unit | 12 kg per unit | 19 kg per unit | 12 kg per unit | 19 kg per unit | 2,5 kg | ||||||||

| Maximum expansion | Stackable up to 3 units | Up to 2 units can be stacked | Up to 3 units can be stacked | Up to 2 units can be stacked | Up to 3 units can be stacked | n/a | ||||||||

| Rotation speed | 20–400 min-1 (3mm: 1'000 min-1) depending on load and stacking | 20–400 min-1 depending on load and stacking | 20–400 min-1 depending on load and stacking | 20–400 min-1 depending on load and stacking | 20–400 min-1 depending on load and stacking | 20 – 200 min-1 | ||||||||

| Shaking throw | 3 mm / 25 mm / 50 mm / adjustable | 25 mm / 50 mm | 25 mm / 50 mm | 25 mm / 50 mm | 25 mm / 50 mm | 25 mm | ||||||||

| Temperature | Without cooling max. 10 °C above AT to 65 °C; Minimum temperature from 4 °C depending on cooling system | 5 °C above ambient temperature to 65 °C |

6 °C above RT to 65 °C 15 °C below RT to 65 °C (with base cooling) 12 °C below RT to 65 °C (with top cooling) |

5 °C above ambient temperature to 65 °C |

6 °C above RT to 65 °C 15 °C below RT to 65 °C (with base cooling) 12 °C below RT to 65 °C (with top cooling) |

4 °C to 60 °C | ||||||||

| Standard parameters | Temperature, rotation speed, timer | Temperature, rotation speed, timer | Temperature, rotation speed, timer | Temperature, rotation speed, timer | Temperature, rotation speed, timer | Rotation speed, timer | ||||||||

| Optional parameters | Cooling, humidity, CO2 | Cooling, Humidity, CO2 | Cooling | Cooling, Humidity, CO2 | Cooling | n/a | ||||||||

| Ambient humidity (rH) | Up to 85 % non-condensing | Up to 85 % non-condensing (setpoint 37 °C / 25°C AT) | Up to 85 % non-condensing | Up to 85 % non-condensing (setpoint 37 °C / 25°C AT) | Up to 85 % non-condensing | n/a | ||||||||

| Power supply | 115/230 V ± 10%, 50/60 Hz | 115/230 V ± 10 %, 50/60 Hz | 115/230 V ± 10%, 50/60 Hz | 115/230 V ± 10 %, 50/60 Hz | 115/230 V ± 10%, 50/60 Hz | 110/230V ±10 %, 50–60 Hz | ||||||||

| Interface | Ethernet | Ethernet | Ethernet | Ethernet | Ethernet | |||||||||

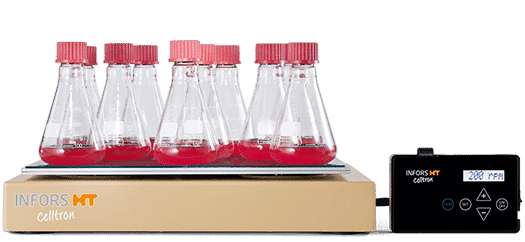

| Go to Minitron | Go to Multitron Standard | Go to Minitron | Go to Multitron Standard | Go to Celltron | Go to Test tube holder for shakers | Go to Box for Microtiter Plates | Go to Universal trays | Go to Fixed-configuration trays | Go to Trays for microtiter plates and deep-well plates | Go to Sticky Stuff |