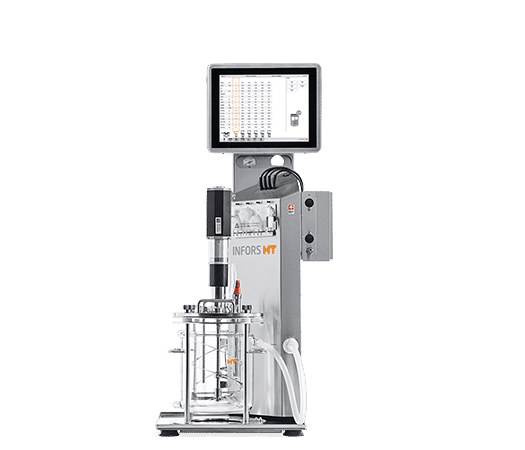

Simultaneous saccharification and fermentation (SSF) in a bioreactor

Production of ethanol from lignocellulosic starting material (such as wood) is a two-phase process: enzymatic hydrolysis to release the sugar, followed by fermentation itself. A sensible option for saving time and avoiding the need to purchase two pieces of equipment is to combine both process steps into a single system known as SSF (simultaneous saccharification and fermentation).

Optimum mixing of different substrates

A bioreactor for SSF has to have a powerful drive, as this is the only way of thoroughly mixing not only highly viscous substrates containing large amounts of dry material, but also the liquefied form that arises following hydrolysis. And because the mixing properties of solids can vary substantially, customers also have a variety of stirrers to choose from.Temperature control for sensitive solids-containing media

Heat transfer in substrates that contain solids is lower than that in liquids. A two-fold, precise temperature-control process — one acting both within the substrate as well as within the double mantle surrounding the bioreactor — ensures optimum temperature management throughout the entire bioprocess. This prevents the interior wall of the reactor from overheating, leaving the enzymes undamaged..Large ports for simple substrate addition

Adding solids to bioreactors designed for liquids can sometimes be difficult. This is why SSF bioreactors have an unusually large port that allows users to dispense solids into the culture vessel easily.Analyzing the hydrolysis process

The bioreactor records the motor torque in real time, allowing researchers to draw conclusions about the viscosity of the culture medium and thus about the progress of hydrolysis. Whereas the viscosity of the solids-containing substrate is initially high, enzymatic hydrolysis will cause it to drop continuously until the medium is a liquid. One way that researchers can use this information is for determining the ideal time to introduce the yeast and begin fermentation.The efficient route to biofuel production

We are happy to advise you

Your solution for solids-containing enzymatic hydrolysis

Labfors 5

Version for solid substrates and enzymatic bioprocesses

Very powerful motor for optimum mixing

40 mm port for easy solids addition

Precise, gentle temperature control

Optional motor torque notification

Techfors

Pilot bioreactor built according to your requirements

Stainless steel vessel with up to 1000 L total volume

Selection of different stirrers, spargers and ports

«This bioreactor was developed in close collaboration with researchers. We have, therefore, achieved a level of optimization which meets the specific requirements for solid and enzymatic bioprocesses.»