Pilot Bioreactors

Points to consider when buying a pilot-scale bioreactor:

1. What is the maximum volume of culture needed?

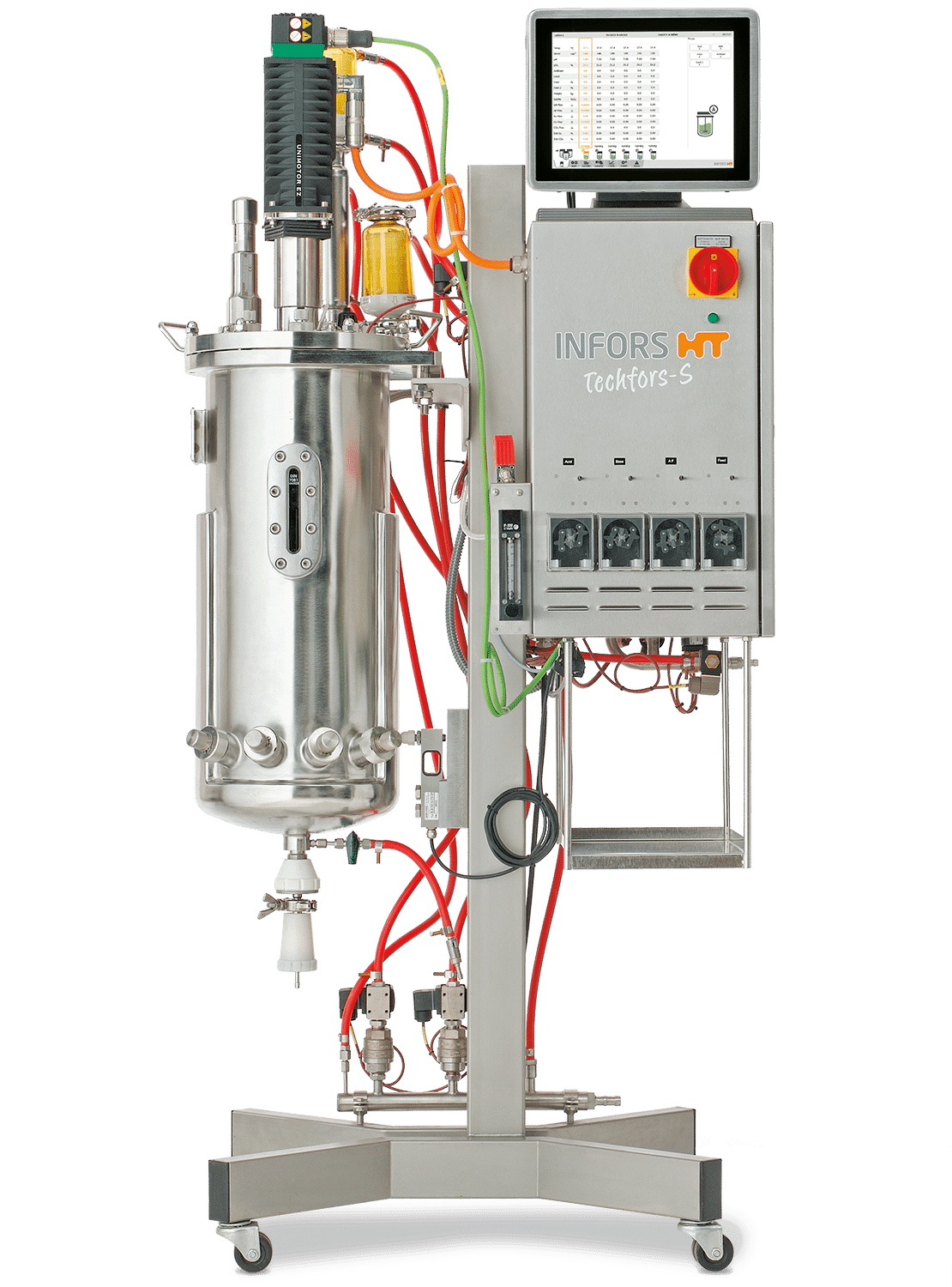

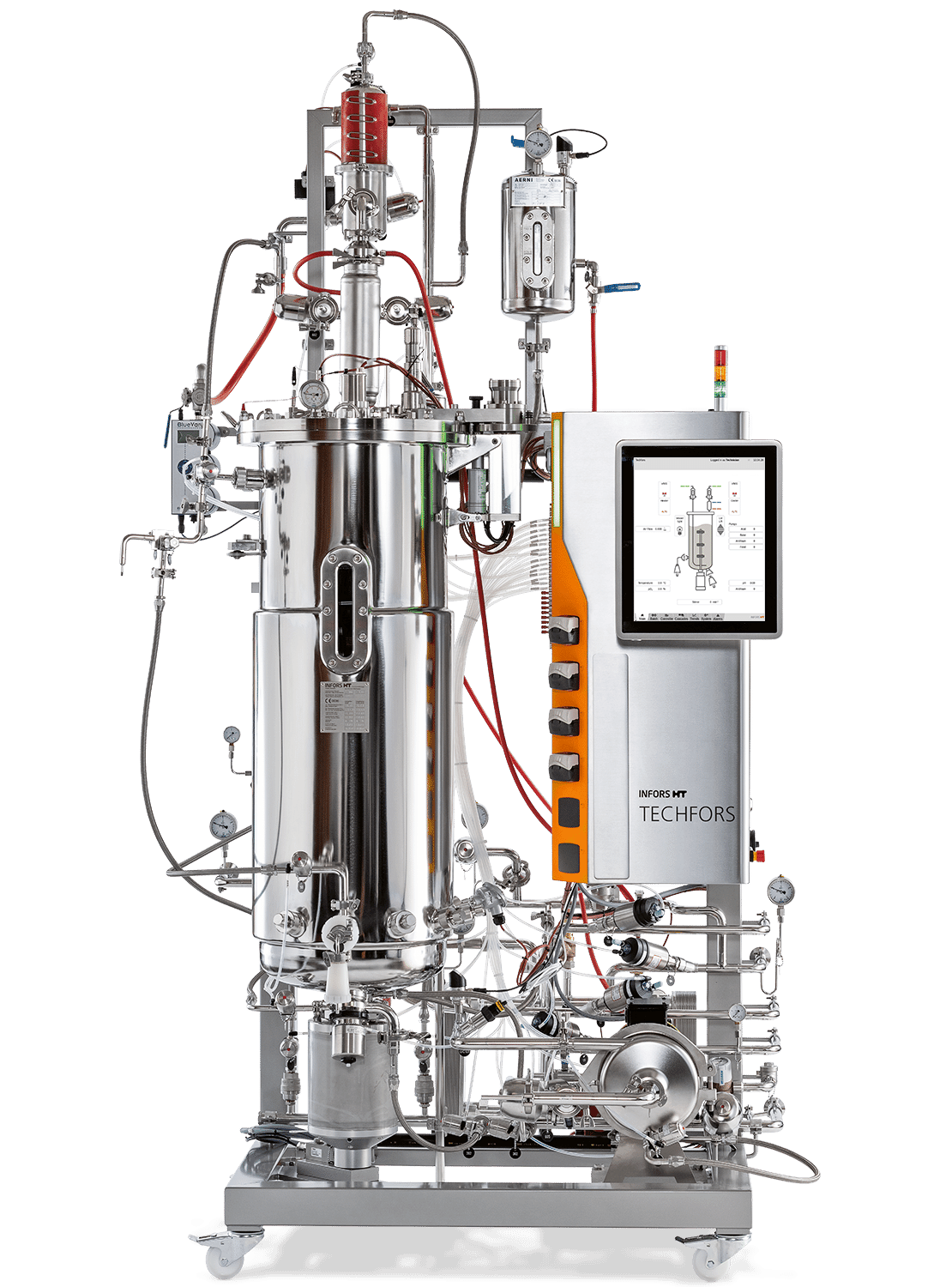

If the answer is 10-30 litres, then a smaller system can be specified which will take up less space, can have it’s own steam supply and is easier to operate for users moving from bench scale systems. Larger systems can be installed in a laboratory environment but that is usually limited to no more than 100 litres working volume. Above this size, a dedicated space in a pilot hall or separate facility will be required.

2. How easy is it to clean and maintain the bioreactor?

Systems up to 100 litres working volume can be mounted on lockable castors for easy access to the rear for service or cleaning behind the unit. The vessel interior and process pipework can be cleansed with an optional Clean In Place (CIP) capability. An open frame design ensures all components are accessible.

3. What about qualification?

A full service can be provided as an option, including

- Design Qualification (DQ) - DQ

- Installation Qualification - IQ

- Operational Qualification - OQ

- Factory Acceptance Test - FAT

- Site Acceptance Test - SAT

In addition, professional installation, commissioning and training can all be provided on request. The documentation provided will cover your needs for process validation to the highest regulatory standards e.g. for the Food and Drug Administration (FDA).

4. How easy is it to make the step from bench-scale to pilot bioreactors?

The main point of interaction for users is the Human Machine Interface (HMI) on the control panel. This is an extension of the bench-scale system, with the same options in the same places plus the extras needed for cleaning, steilization and extra process parameters. External connectivity and links to bioprocess software are all based on industry-standard OPC. This makes mixed groups of bioreactor sizes and types easy to set up in bioprocess software.

5. What if I’m unsure as to what I will actually need to meet my objectives?

In addition to comprehensive documentation and drawings, each pilot system beyond 30 litres will be treated as a project. The design and engineering skills of our Design Office will be available to you for help with specification. As well as the bioreactor, this includes advice on factors such as service provisions e.,g. water quality, air supply and electrical connections.

6. What about backup and support?

After Sales and Service are a key part of the buying process often not considered too closely until they are needed. Backup is provided for repairs, maintenance and upgrading, with compregensive service agreements avaialble.