Culturing stem cells in a bioreactor

Successfully culturing stem cells in a bioreactor requires precise monitoring and control of certain critical process parameters, such as pH, dissolved oxygen concentration and temperature, as well as biochemical parameters, such as the concentrations of important nutrients, metabolites and growth factors. Another particularly important factor for stem cell cultivation in a bioreactor is preventing cell damage by minimizing the shear stress caused by stirring and gassing. This holds true whether you are culturing stem cells with suspension cells, cell aggregates or stem cells on microcarriers.

Precise control of the dissolved oxygen concentration

Because it influences stem cell differentiation and division, the dissolved oxygen concentration must be controlled very precisely. The ideal solution is a gassing strategy involving air, N2 and O2, each with its own mass flow controller. An important factor is making sure enough oxygen is available to cells i.e. ;keeping the kLa value of the bioreactor high despite a low, gentle gassing rate. The system also needs to include a separate CO2 line for pH control, as well as an option for headspace gassing.

Thorough mixing with little shear stress

Thorough mixing is indispensable for maintaining homogeneous conditions within the culture vessel. Short mixing periods reduce concentration gradients which can damage cells. They can arise, for instance, when introducing base reagent or nutrient medium. Stem cells are especially sensitive to shear forces, which means that thorough mixing with low power input and uniform energy distribution is important. Key features of suitable bioreactors include optimum reactor geometry and a stirrer that is gentle to cells and correctly positioned.Continuous monitoring of process-critical parameters

The ability to culture cells reproducibly requires a detailed look inside the cultivation process. Additional sensors such as redox, exhaust gas, viable cell density and biomass sensors, allow users to monitor critical parameters continuously. On the basis of these data, bioprocess software can then continuously calculate additional parameters such as RQ, allowing the system to respond quickly and automatically to changing process conditions.Microcarriers as a solution for adherent cells

Adherent cells i.e. stem cells that only grow if they can affix themselves to a matrix, are often cultured in bioreactors with the aid of microcarriers. These are available in a variety of materials and are frequently used with spin filters. Microcarriers with cells cannot pass through the filter membrane, causing the cells to accumulate in the bioreactor and allowing the user to harvest cell-free medium.Your stem cell bioreactor

Contact us for one-on-one consultation.

Bench-top bioreactors for stem cells:

Minifors 2

The award-winning, all-in-one system for cell cultures

Vessels: 1,5 L - 6 L

- Gentle stirring system capable of reaching up to 600–1

- Optimum gassing with up to 5 MFCs

- Includes a “cookbook” explaining bioprocess fundamentals.

Maximize Efficiency:

Save time and resources by running multiple experiments simultaneously, increasing your lab's productivity.

Precision and Reliability:

Our incubator shaker is engineered for optimal performance, ensuring that your valuable microbial cultures thrive in a controlled environment

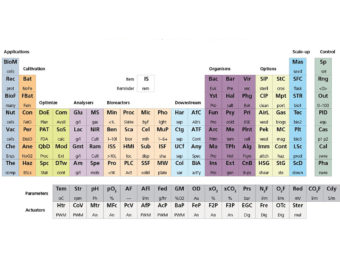

eve® – Bioprocess software for bioreactors

Workflow-oriented planning tools and comprehensive options for bioprocess control and monitoring

Location-independent monitoring and control of bioprocess parameters

Detailed reporting according to GMP

Validation according to FDA 21 CFR Part 11

«Stem cells are highly sensitive to shear forces, which means that thorough mixing with low power input is important.»