Humidification systems are vital for sucessful small-volume and long-lasting cultivations in the incubator shaker (e.g. screening in microtiter plates or cell culture). The different systems available on the market have one primary focus: to reduce evaporation losses by increasing the humidity levels inside the incubation chamber. However, there are significant differences in terms of quality, humidity control and sterility. This blog post highlights the Pros and Cons of the 3 most commonly used humidification systems.

Why do I need humidity control in my incubator shakers?

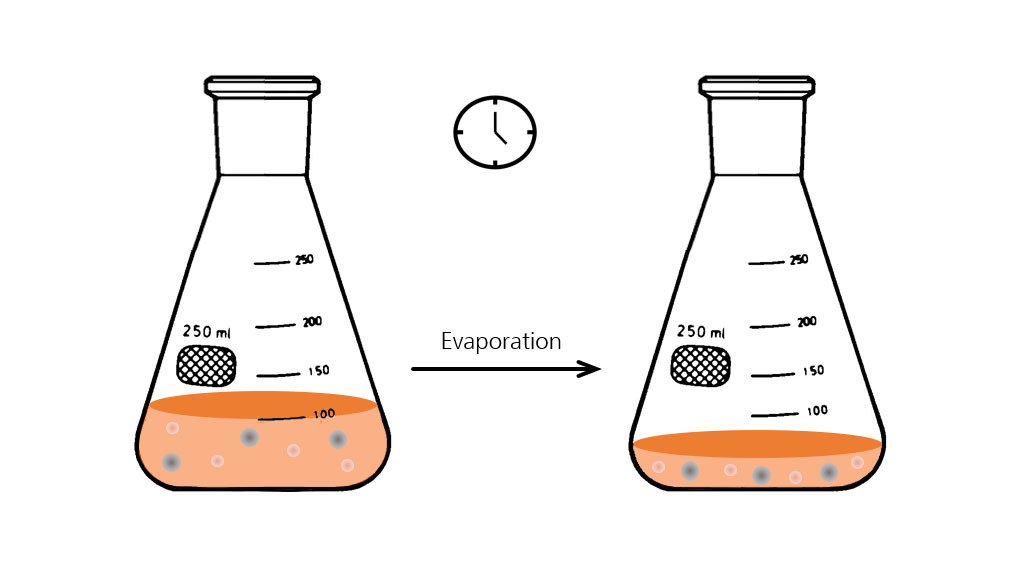

During the cultivation process, water from the culture media evaporates gradually within the incubator shaker. This is especially true when working with small volumes in microtiter plates or with long cultivation periods (e.g. cell culture). Evaporation significantly increases the concentration of the culture medium over time. This can result in growth limitations and reduced productivity due to many factors, including:

- Increase in osmolarity

- Increase in concentration of salts and ions

- Changes to oxygen solubility

- Increased viscosity

A critical factor to consider is that the losses from each well or vessel will vary. This will compromise the statistical validity of any results, meaning screening processes and Design of Experiment (DoE) studies will subsequently suffer.

Evaporation in shake flasks: Working temperatures above ambient and long cultivation periods result in an inevitable loss of liquid due to evaporation.

How do you avoid evaporation in an incubator shaker?

Fortunately, evaporation can be minimized by increasing the humidity levels in the shaker. Different solutions to acheive this can be applied. Some are simple and can be set up in minutes, whilst others are more sophisticated and include specific measurement and control systems. In the following, different solutions for incubation shaker are compared below:

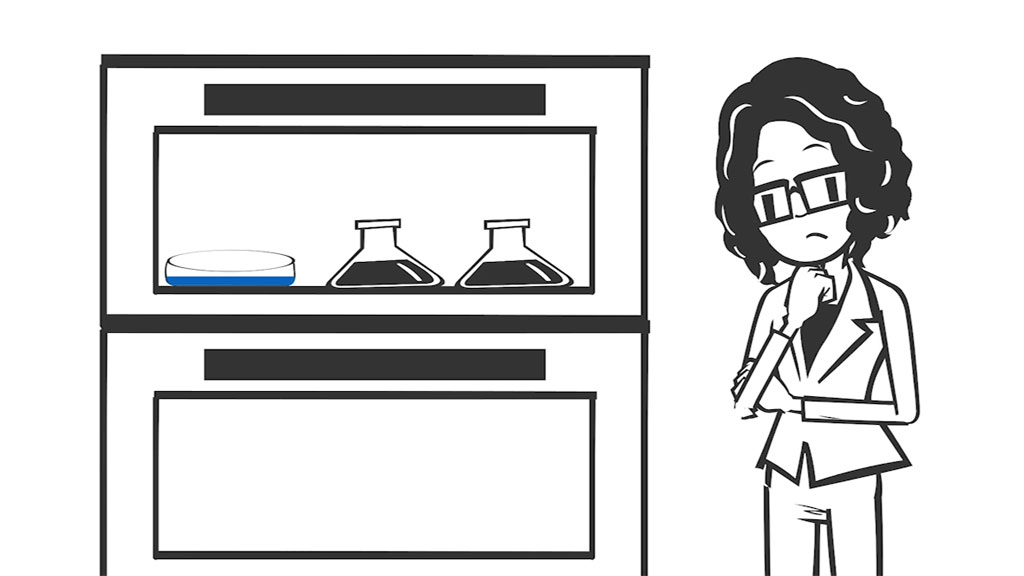

The simple solution: Open water bath

If humidity control is not available, there are still other solutions that can be applied. A free-standing water bath can be placed in the chamber to keep a moist environment. Using a row of wells on a microtitre plate could have the same effect. This is not ideal but may provide a short-term solution. Open water baths bear an increased risk of contamination because both, the condensed water and the water in the container provide a breeding ground for mold, which could contaminate your culture. Moreover, the relative humidity is not precisely controlled, so condensation is likely to occur. However, this type of humidification system can be set up quickly and is cost effective.

Schematic representation of an open water bath in an incubator shaker.

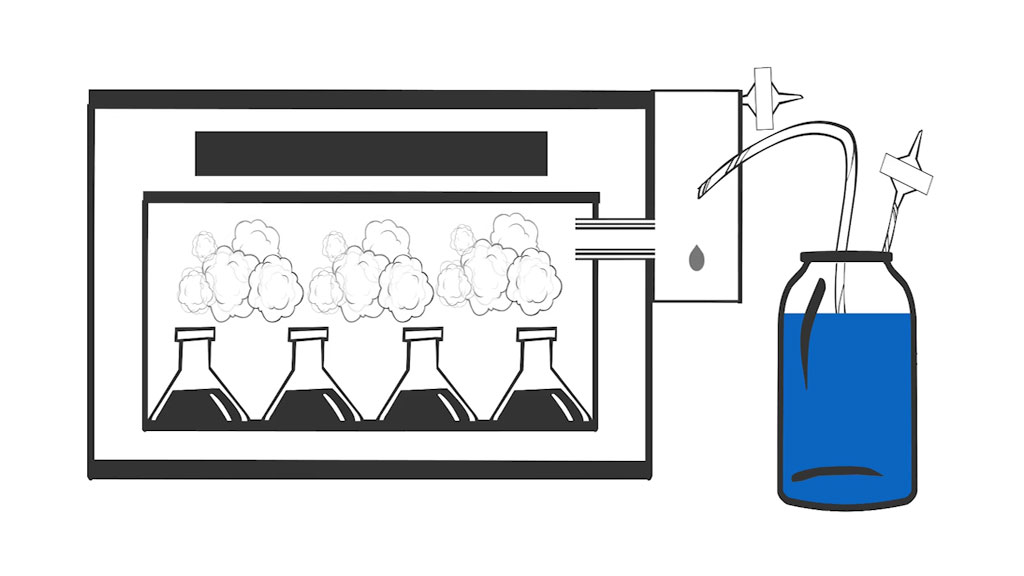

The advanced solution: Direct steam humidification

Direct Steam Humdification is an option, which can be integrated into some incubator shakers. It provides a one-sided control of the relative humidity (rh) in the incubation chamber up to 85 % rh. This is an effective way to reduce loss through evaporation. Single drops of water are flash vaporized in a hot pod and directly led into the incubation chamber supplying a hygienic source of water steam. A heated door panel is added to allow a clear view of the cultures without condensation. This is more advantageous compared to the water bath solution as the conditions inside the shaker are reproducible and comparable as are the results. Another benefit of the direct steam humidification system is that the humidity levels can be changed, logged, and saved in a bioprocess software.

The high-end solution: Bidirectional humidity control

This is the most precise solution available as it can both increase and decrease the humidity levels inside the incubation shaker. Increasing the humidity works the same way as the direct steam humidification system, and is just as hygienic and accurate. The humidity levels can be decreased by blowing ambient dry air through a sterile filter into the cultivation chamber. The system can therefore achieve a condensation free temperature reduction and lower the risk of an unexpected rise in ambient humidity when putting cold flasks into the warmer shaker. The bidirectional control enables the user to choose the humidity setpoint from a broad range while ensuring condensation-free operation even at low incubation temperatures. This system allows for reproducible and comparable results inside the shaker with regards to the evaporation. It is considered to be the “gold standard” and can be changed, logged, and saved in a bioprocess software.

Schematic drawing of a bidirectional humidification system including water-inlet as well as dry air inlet over sterile filters.

The quick solution for microtiter plates: Box for microtiter- and deep-well-plates

Another option to restrict evaporation losses is to use a barrier. In this case, a box with an optional air filter. It reduces evaporation in microtiter and deep-well plates in incubation shakers without the need for humidification. This method minimizes the contamination risk as the box is autoclavable and can be loaded under a clean bench. Thereby sterile conditions inside the box are maintained.

INFORS HT box für microtiter plates: The box can hold up to three layers of microtiter plates and can be fixed on different trays. It can be used for all microbial and cell applications and is strongly recommended for cell culture in microtiter plates.

Summary

To prevent evaporation causing the media concentration to increase and cause any subsequent negative effects on cells and product, different types of humidification systems are available. They all have one common objective: to reduce the evaporation losses by increasing the humidity inside the incubation chamber. Which type of the system is the most suitable depends upon the application, equipment and severity of the evaporation effects.

- The water bath is the simplest solution. On the one hand it can be set up by the customers themselves cost-free, but on the other hand it does not allow for any form of control. Therefore, condensation and contamination are likely to occur.

- A more advanced solution is to use a direct steam humidification system which allows a controlled increase of the humidity levels inside the shaker and thereby provides comparable and reproducible conditions, which are vital to compare results from different experiments. Furthermore, it reduces the contamination risk since there is no open water inside the shaker and only a minimal risk of condensation.

- The high-end solution is the two-sided humidity control which can increase and decrease the humidity inside the chamber. This provides a precise and reproducible bidirectional control of the humidity levels inside the shaker. Open water baths and condensation affects are avoided, which significantly lowers the contamination risk.

- By using a microtiterbox evaporation can be reduced to a minimum – even without a humidification system in the incubation shaker. This method also provides a sterile environment for microtiter plates.

You can find further information about evaporation effects in screening experiments in the Blog Post 5 Key Factors for Reliable Screening Results in Incubator Shakers.