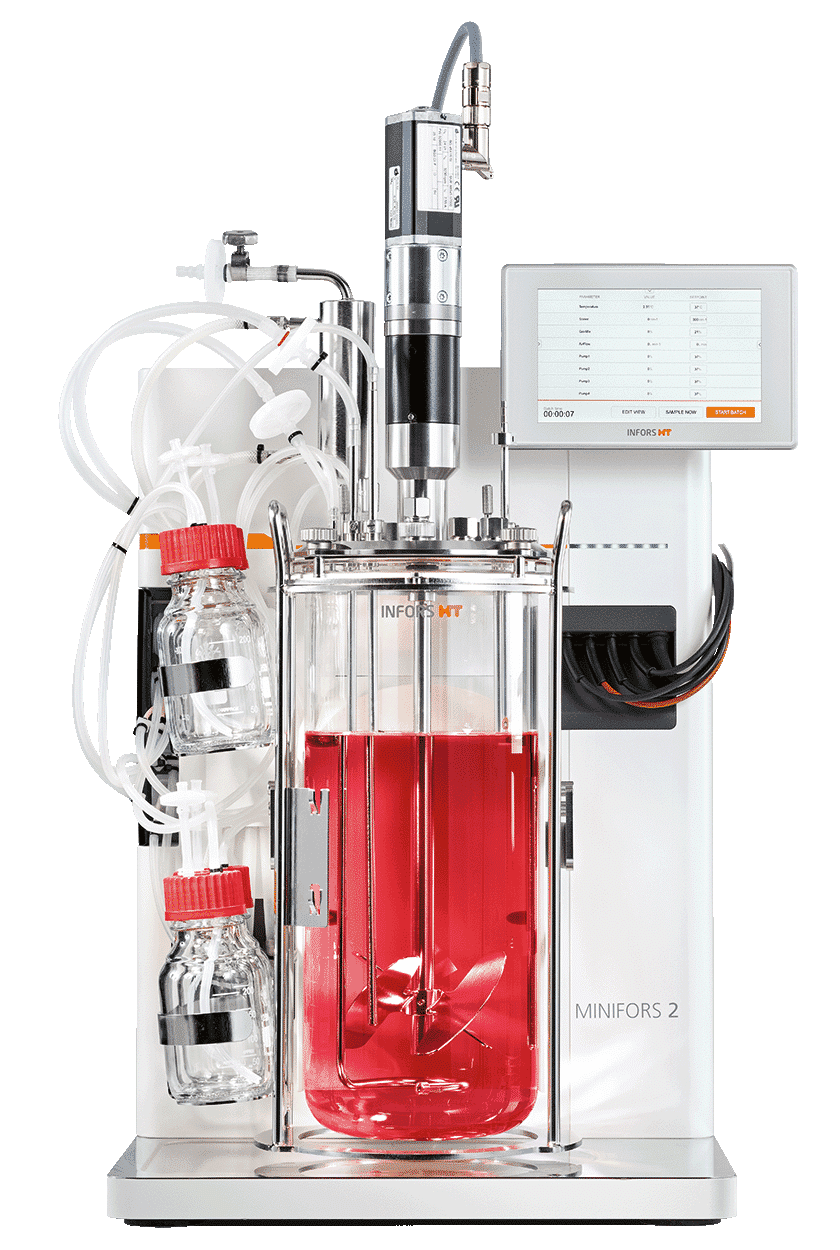

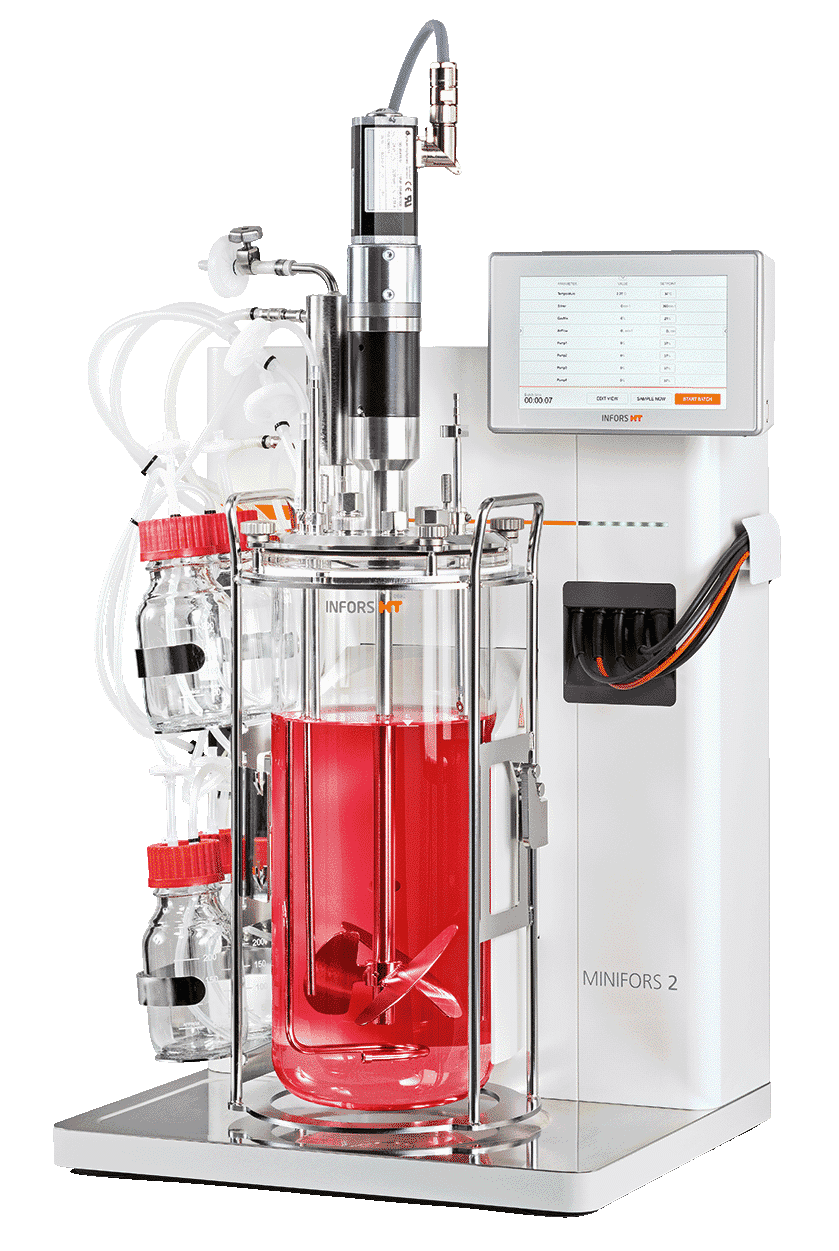

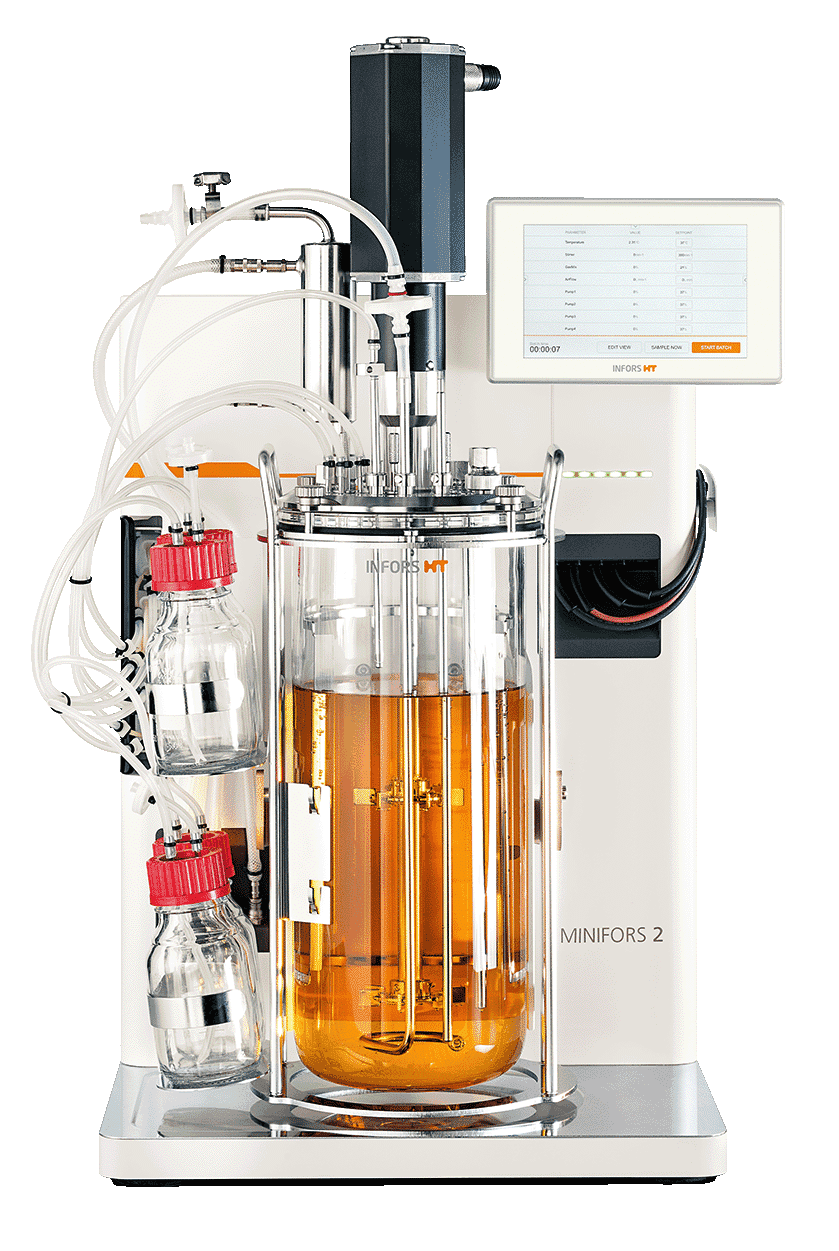

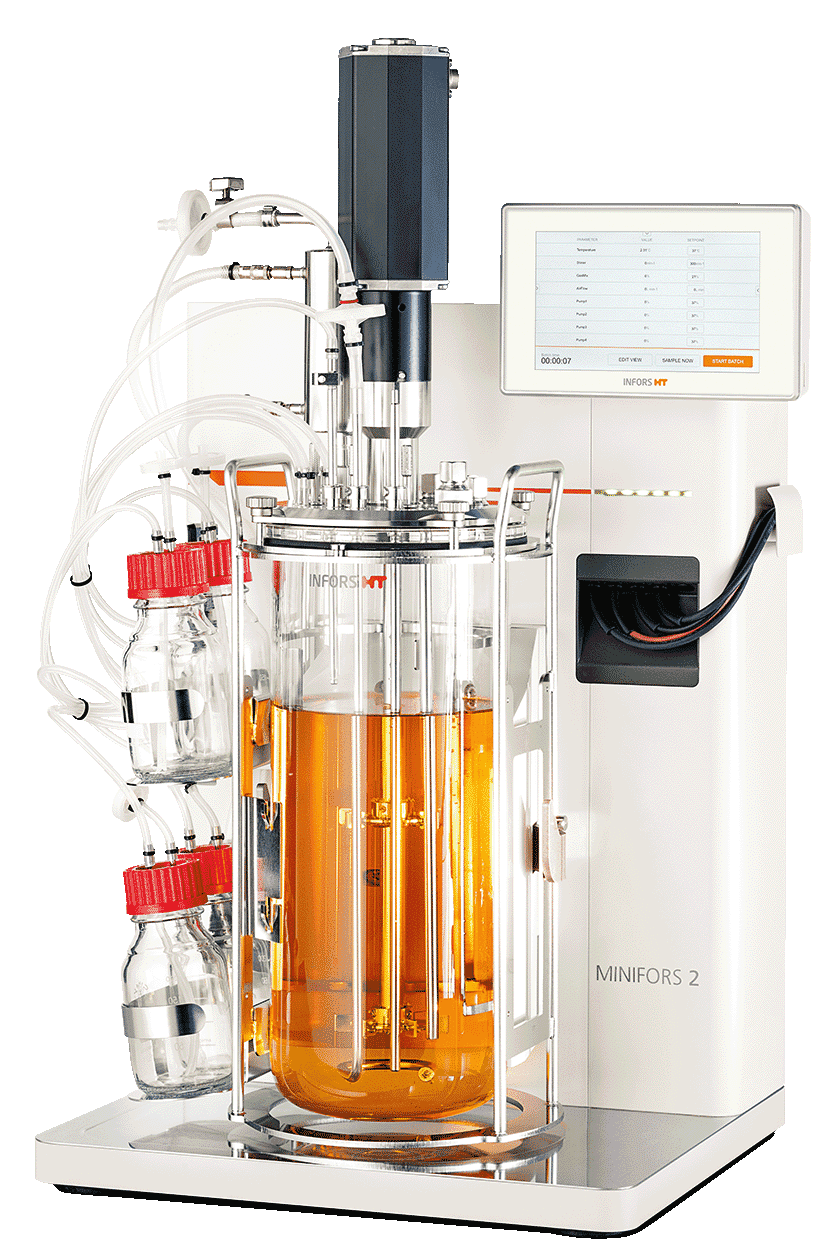

| Vessels | 1.5 L / 3 L / 6 L |

|---|---|

| Working volume | 0.3–1.0 L / 0.6–2.0 L / 1.1–4.0 L |

| Dimensions (W x D x H) | 455 mm x 375 mm x 740 mm |

| Drive | Version for Microorganisms: 150 min-1 to 1600 min-1 Version for cell cultures: 24 min–1 to 600 min-1 |

| Temperature | + 15 °C (Coolant temperature + 5 °C) to 60 °C |

| Gassing per vessel | Version for microorganisms: 2 MFCs up to 2 min-1, version for cell cultures: 5 MFCs up to 0.15 min-1 |

| Pumps per vessel | 4 x configurable (fixed or variable speed) ex-works: 3 x fixed (acid, base, anti-foam), 1 x variable (feed) |

| Pump performance | 0.0034 to 3,52 mL min-1 (standard), 0.017 to 16,13 mL min-1, 0.0012 to 1.12 mL min-1 |

| Ports per vessel | 7,5 mm 4x |

| Connectivity | OPC UA via Ethernet |

| Parallel operation via touch screen controller | 1 unit |

| Sterilisation | Autoclave |

Data Sheets

Flyer & Brochures

Practical Advice

Thank you for your interest!

Please enter your e-mail address in order to download the document.

Application Notes

Manuals

Thank you for your interest!

Please enter your e-mail address in order to download the document.

Thank you for your interest!

Please enter your e-mail address in order to download the document.

Thank you for your interest!

Please enter your e-mail address in order to download the document.

Thank you for your interest!

Please enter your e-mail address in order to download the document.

Thank you for your interest!

Please enter your e-mail address in order to download the document.

Thank you for your interest!

Please enter your e-mail address in order to download the document.

Thank you for your interest!

Please enter your e-mail address in order to download the document.

White Papers

Thank you for your interest!

Please enter your e-mail address in order to download the document.

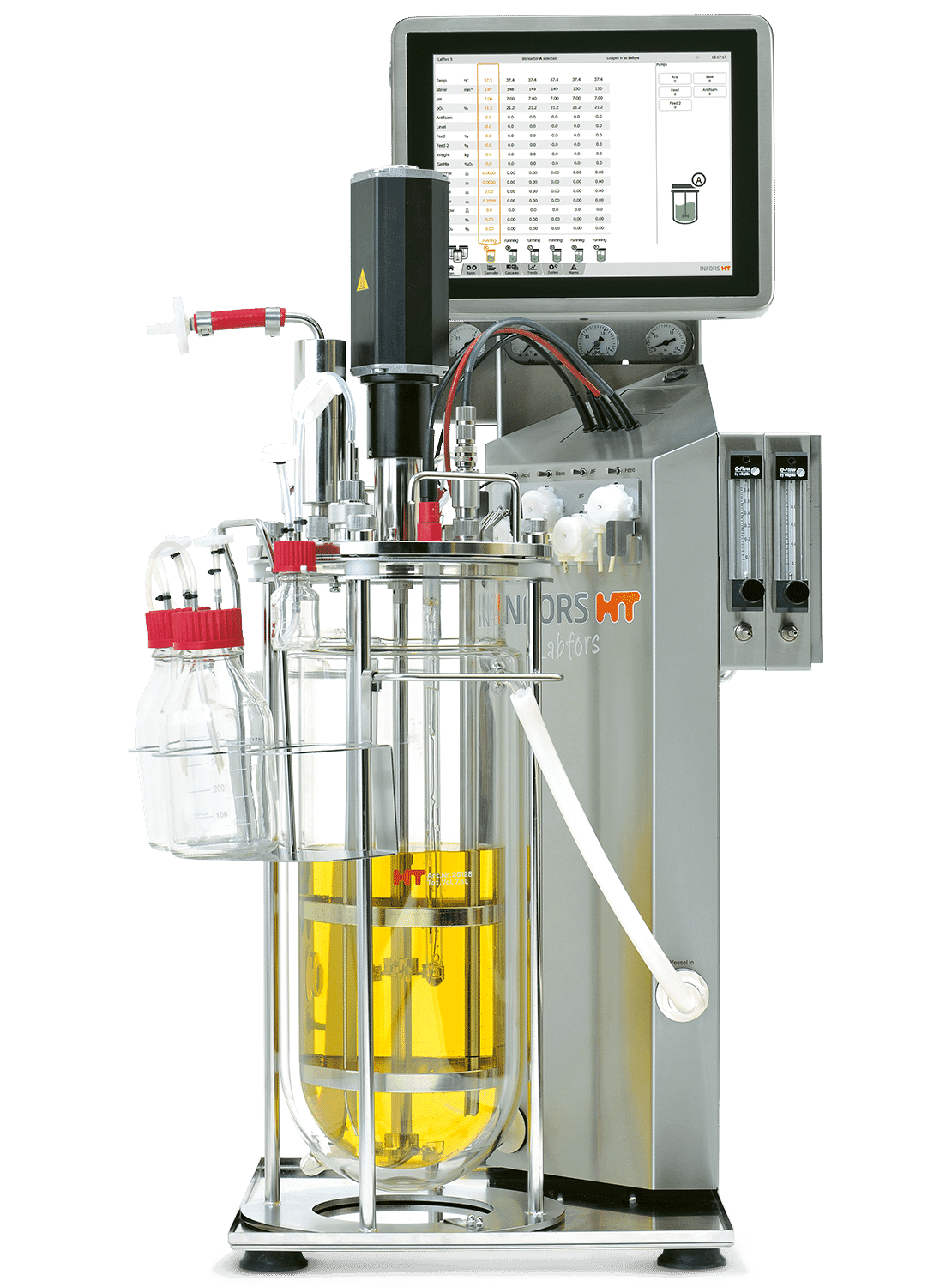

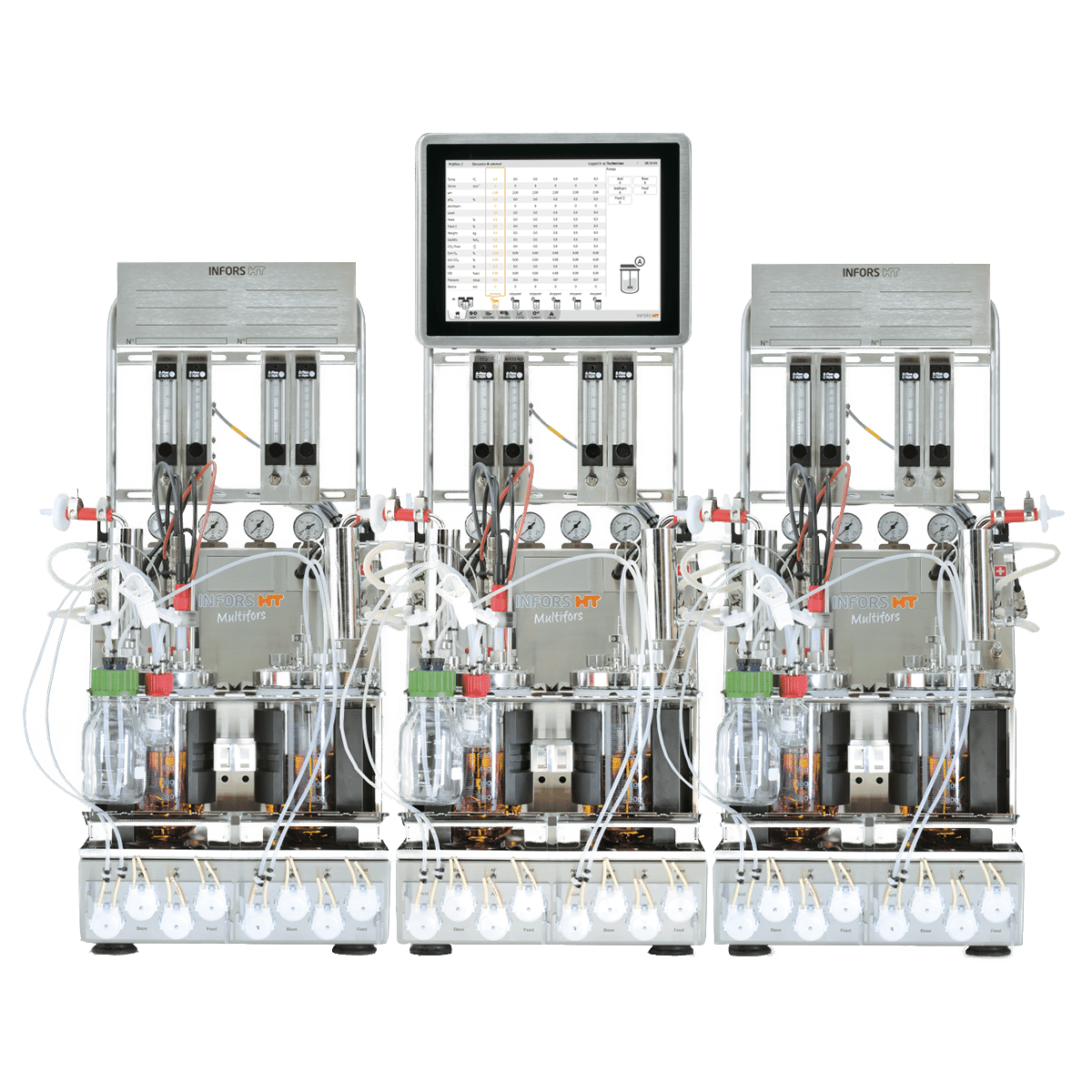

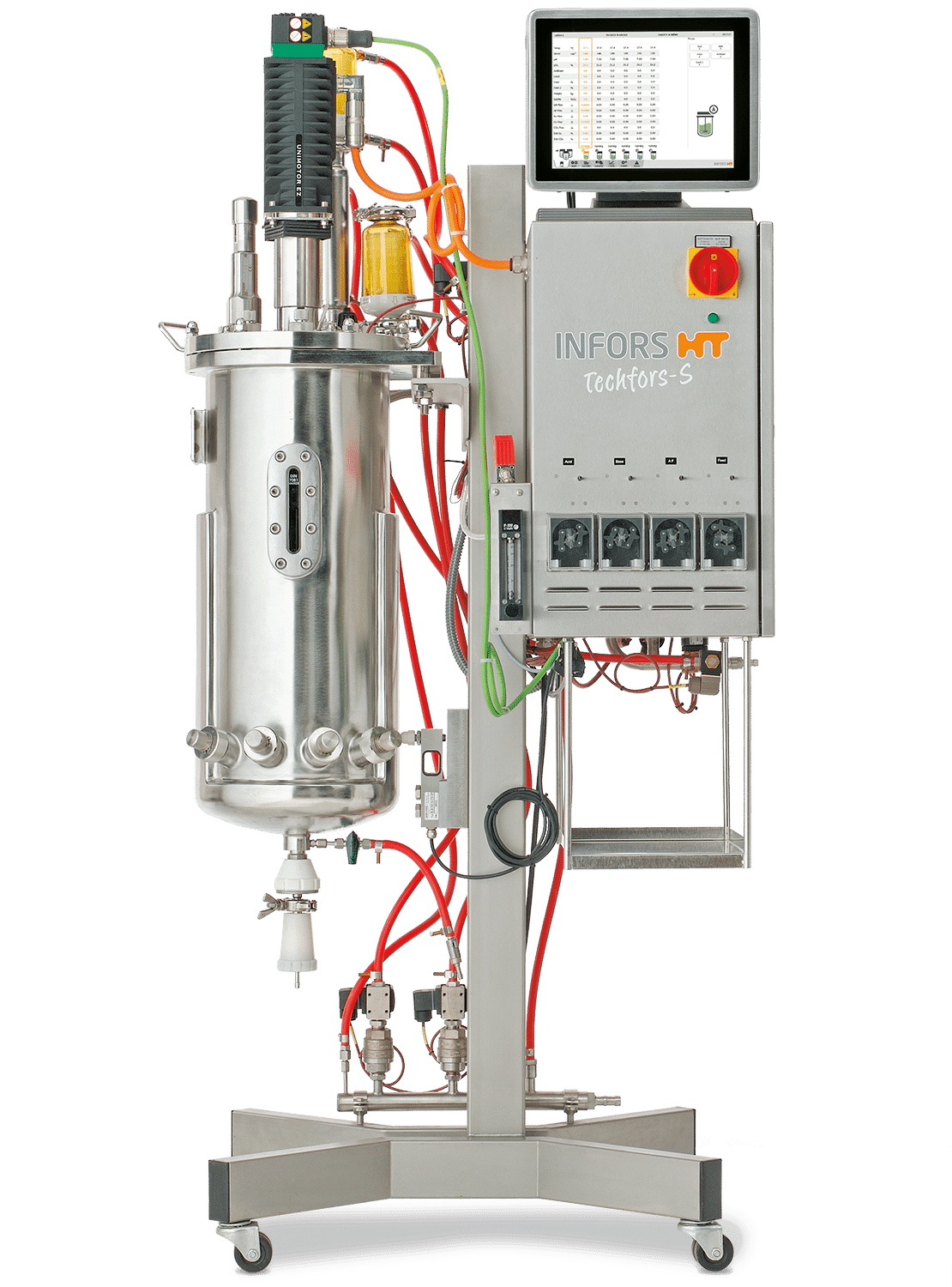

| Minifors 2 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Vessels | 1.5 L / 3 L / 6 L | 0,4 L / 0,75 L / 1,4 L | 2 L / 3,6 L / 7,5 L / 13 L | 15 l / 30 l / 42 l | up to 1000 L | |||||

| Working volume | 0.3–1.0 L / 0.6–2.0 L / 1.1–4.0 L | 0,15–0,25 L / 0,18–0,5 L / 0,32–1 L | 0,5–1,2 L / 0,5–2,3 L / 1–5 L / 2,2–10 L | 3–10 l / 5,3 l–20 l / 6–30 l | up to 660 L | |||||

| Dimensions (W x D x H) | 455 mm x 375 mm x 740 mm | 350 mm x 520 mm x 960 mm | 464 mm x 462 mm x 996 mm | 1017 mm x 934 mm x 1841 mm | Depending on specification | |||||

| Drive | Version for Microorganisms: 150 min-1 to 1600 min-1 Version for cell cultures: 24 min–1 to 600 min-1 | Magnetic drive to 1600 min-1 | Direct drive up to 1500 min–1 | Direct drive to 1200 min-1 | Depending on specification | |||||

| Temperature | + 15 °C (Coolant temperature + 5 °C) to 60 °C | Coolant temperature + 5 °C to 70 °C | Coolant temperature + 5 °C bis 70 °C | Coolant temperature + 5 °C to 79 °C; to 125 °C for sterilisation | up to 79 °C for temperature control; up to 125 °C for sterilisation | |||||

| Gassing per vessel | Version for microorganisms: 2 MFCs up to 2 min-1, version for cell cultures: 5 MFCs up to 0.15 min-1 | Up to 4 rotameters oder MFCs up to 2 min-1 (vvm) | Up to 5 rotameters or MFCs up to 2 min-1 (vvm) | up to 4 MFCs | Depending on specification | |||||

| Pumps per vessel | 4 x configurable (fixed or variable speed) ex-works: 3 x fixed (acid, base, anti-foam), 1 x variable (feed) | 3 fixed, 1 variable, optional 1 additional variable | 3 fixed, 1 variable, optional 1 additional variable 3 | 4 fixed, optional 2 additional variable | 3 fixed, 1 variable, optional 2 additional | |||||

| Pump performance | 0.0034 to 3,52 mL min-1 (standard), 0.017 to 16,13 mL min-1, 0.0012 to 1.12 mL min-1 | Depending on the design from 0,0012 mL min-1 to 3,46 mL min-1 | Depending on version, from 1,2 μl min–1 to 17,1 ml min–1 | |||||||

| Ports per vessel | 7,5 mm 4x | 7 mm 4x | 7 mm max. 4x | Top plate: Vessel bottom: | Depending on specification | |||||

| Connectivity | OPC UA via Ethernet | OPC XML DA via Ethernet | OPC XML DA via Ethernet | OPC XML DA via Ethernet | OPC XML DA via Ethernet | |||||

| Parallel operation via touch screen controller | 1 unit | 3 base units, resp. 6 vessels | up to 6 vessels | - | 1 base unit | |||||

| Sterilisation | Autoclave | Autoclave | Autoclave or LabCIP (microbial version) | Sterilisation-in-Place | Sterilisation-in-Place | |||||

| Go to Multifors 2 | Go to Labfors 5 | Go to Techfors-S | Go to Techfors | Go to CGQ BioR | Go to Optek Turbidity Sensors | Go to Super Safe Sampler |