Our Products

Your needs

Top Solutions

- High-throughput screening in 96-well-plates

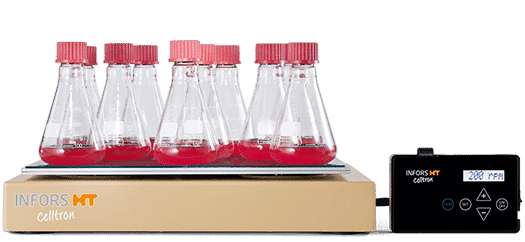

- Cell cultivation in the incubator shaker

- Culturing stem cells in shakers

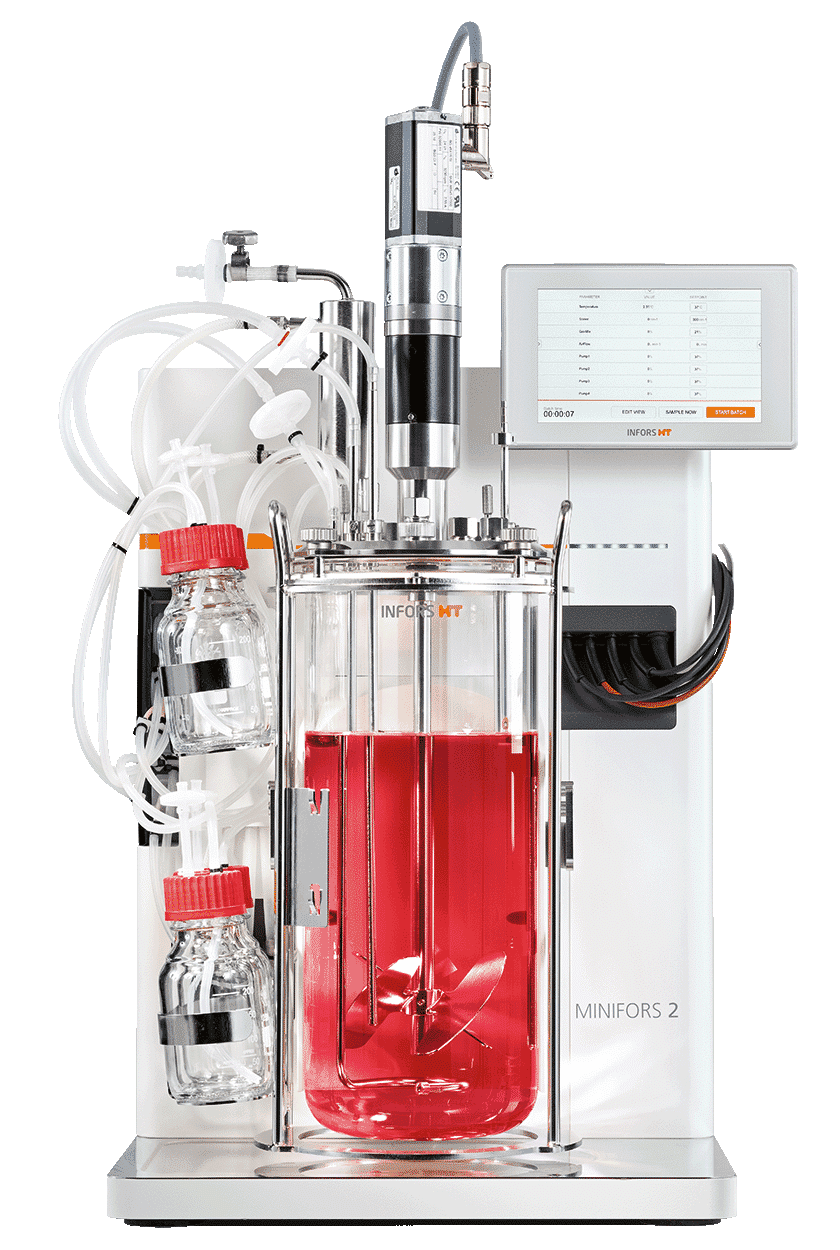

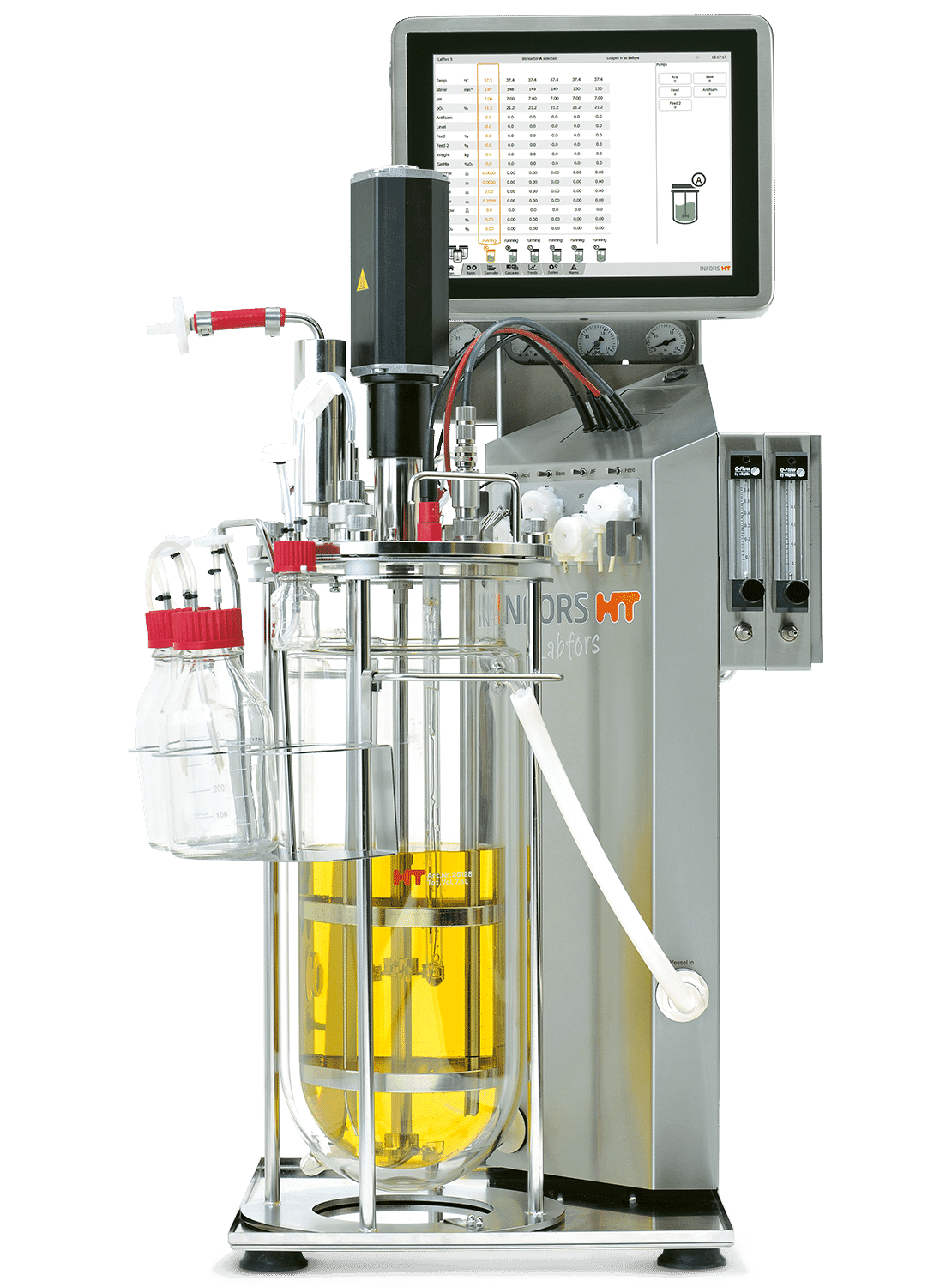

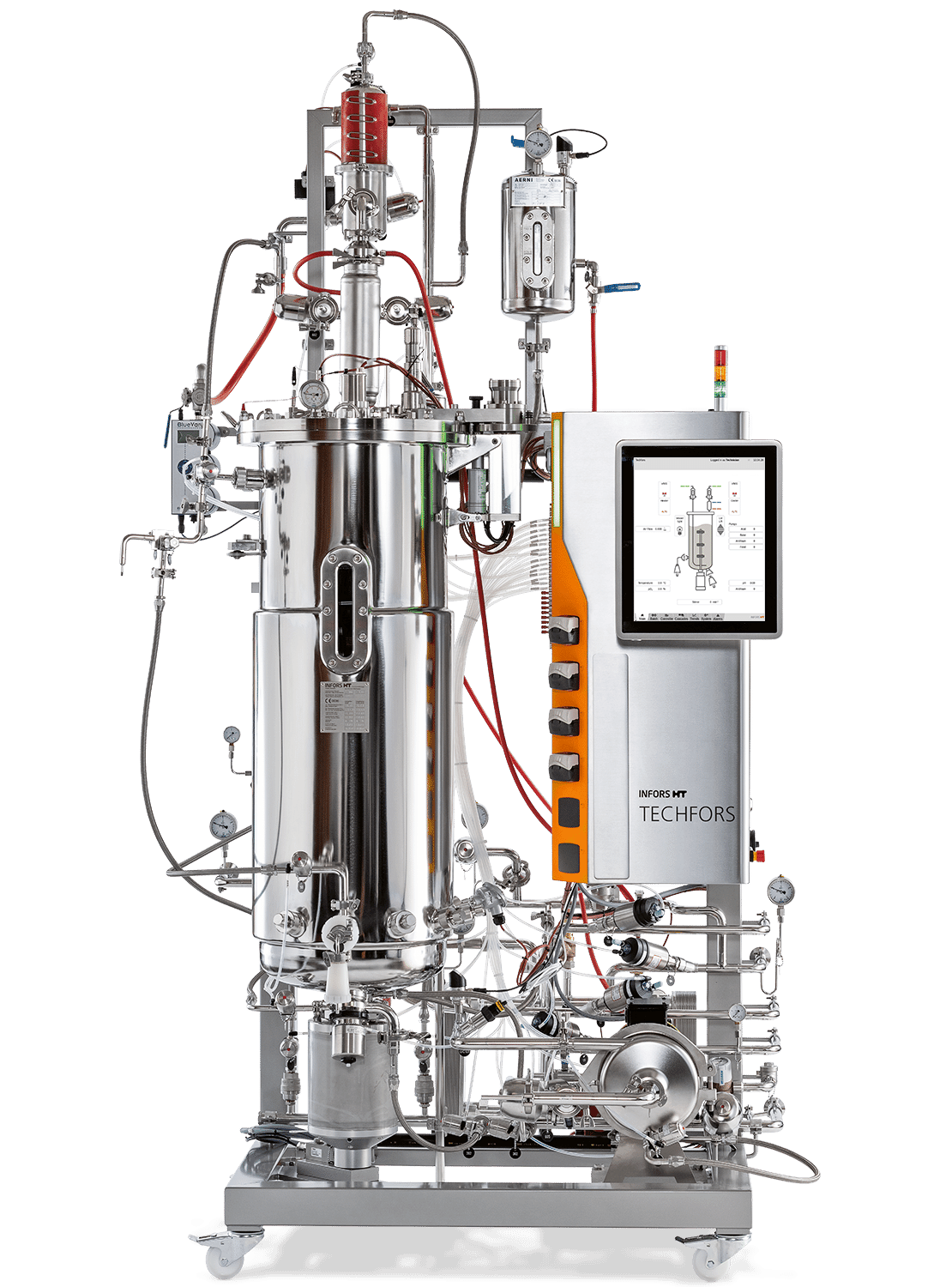

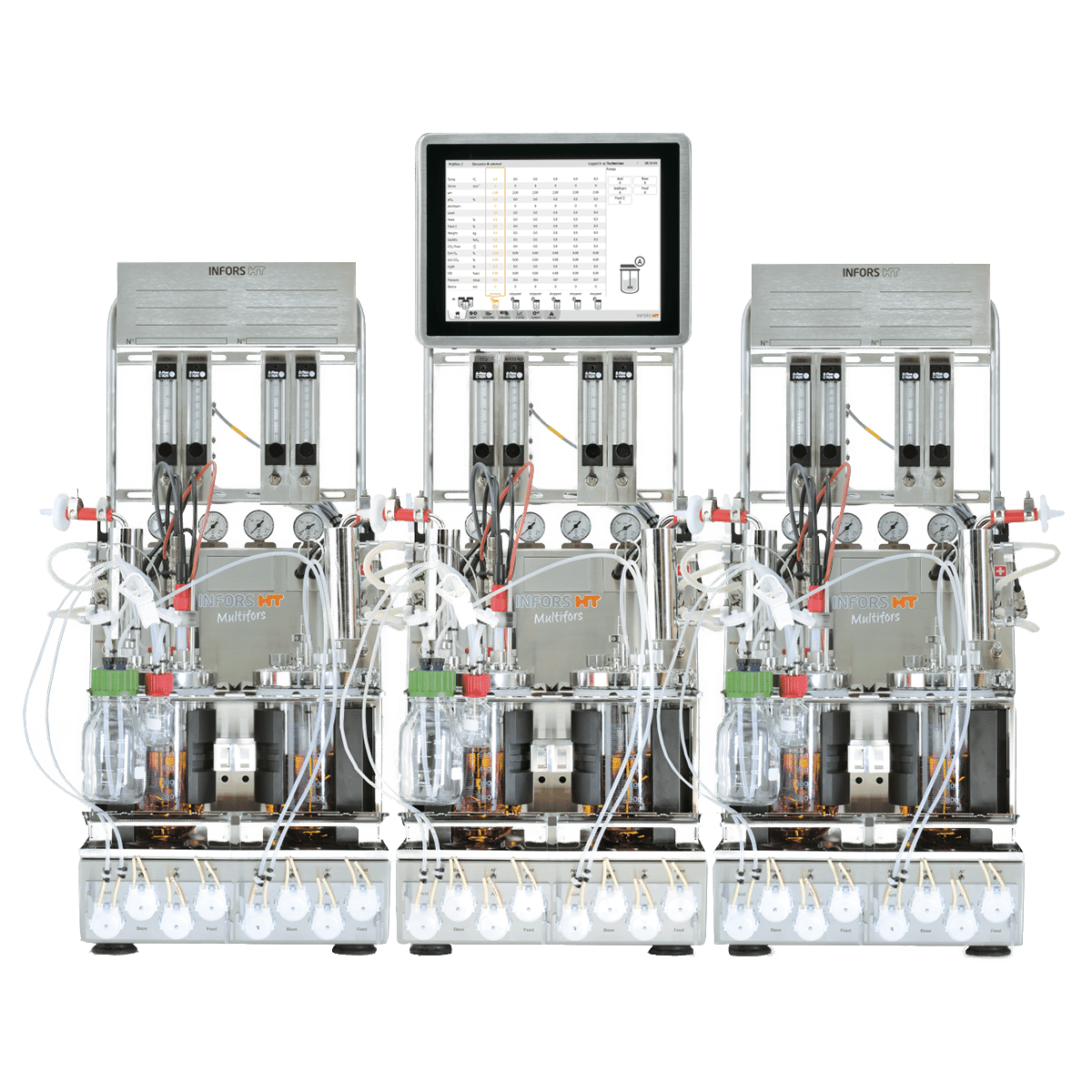

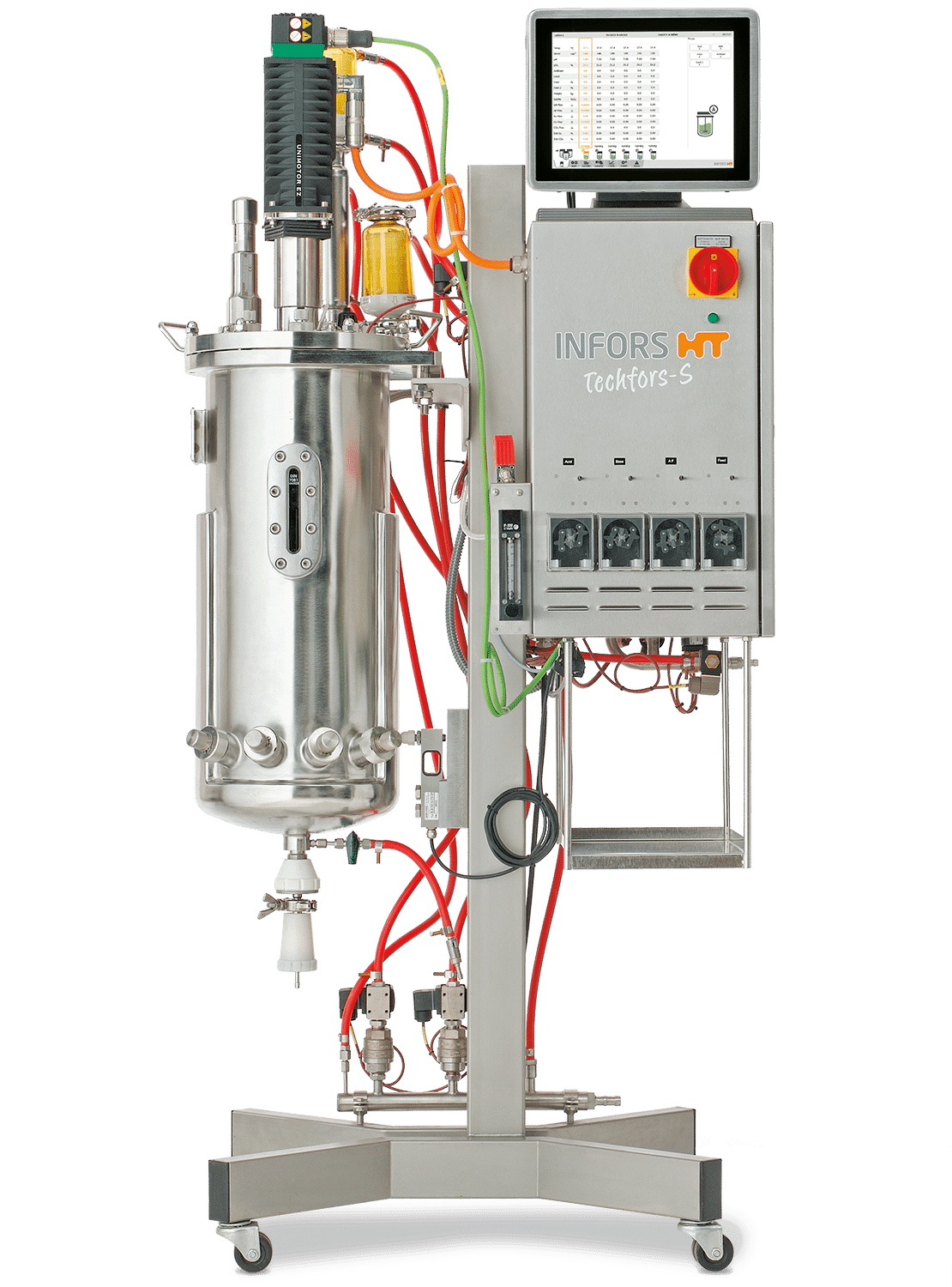

- High cell densities in the bioreactor

- Bioreactors for continuous cultivation with perfusion

- Culturing stem cells in a bioreactor

- Cell culture bioreactors

- Simultaneous saccharification and fermentation (SSF) in a bioreactor

- Chemostat bioreactors for continuous cultures