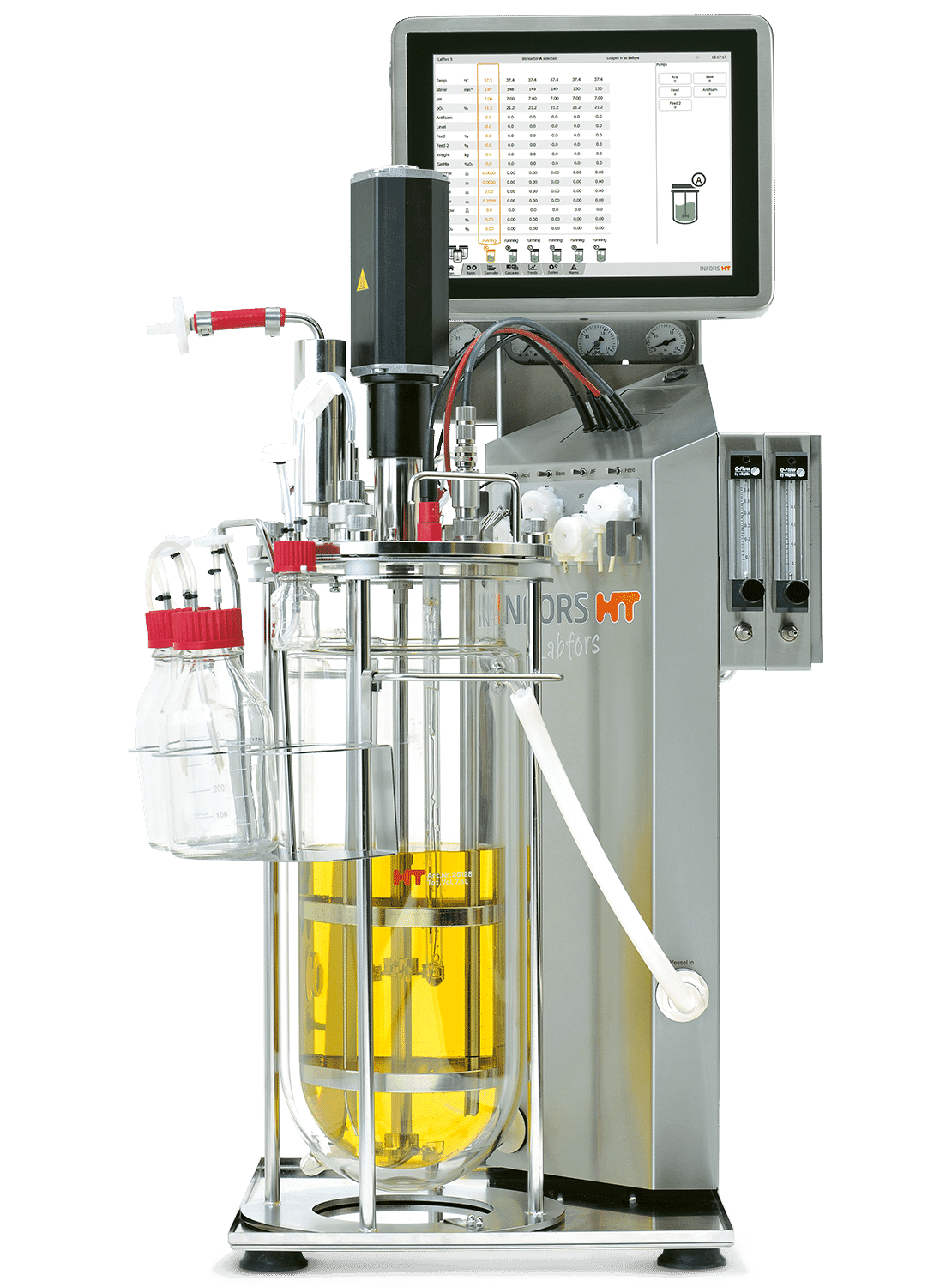

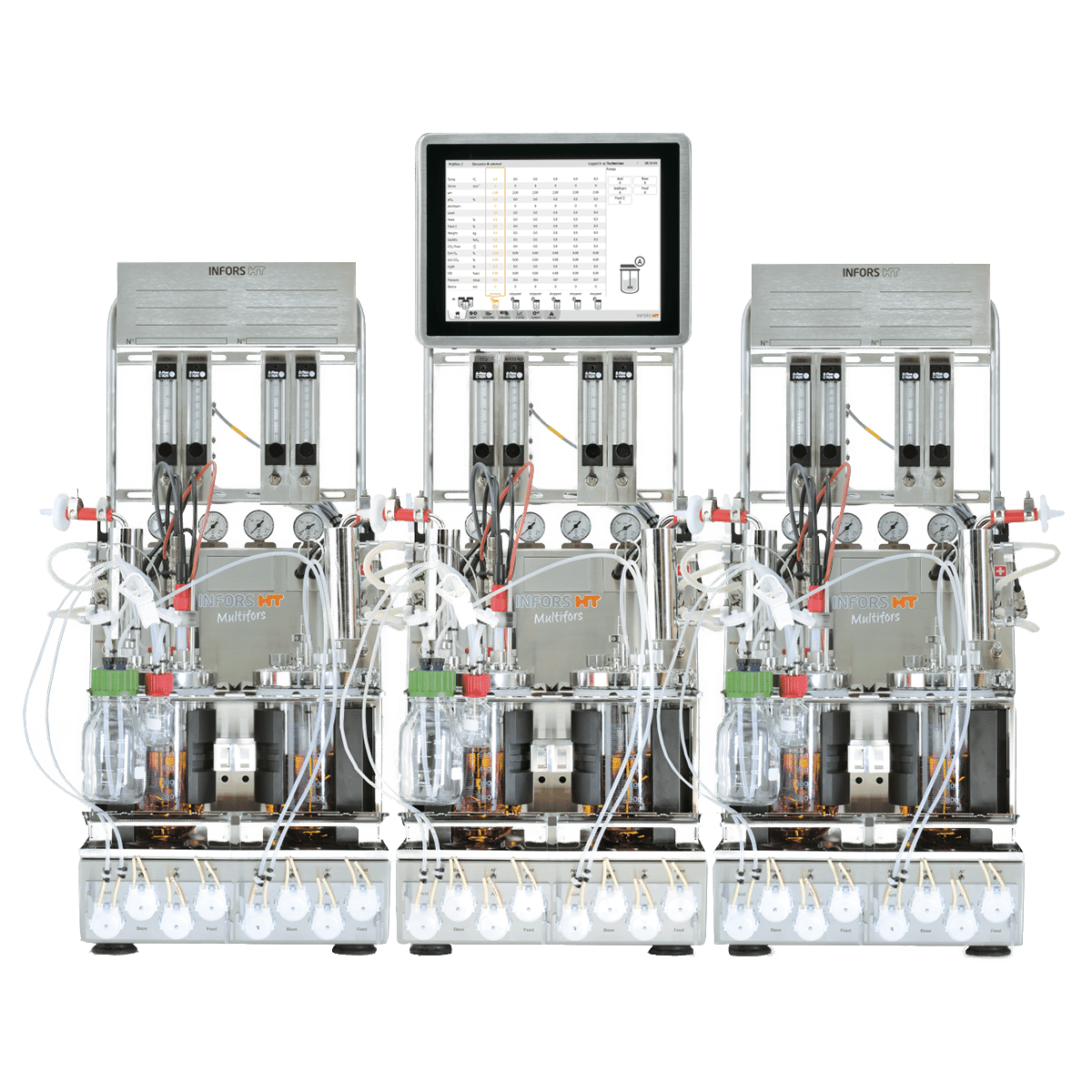

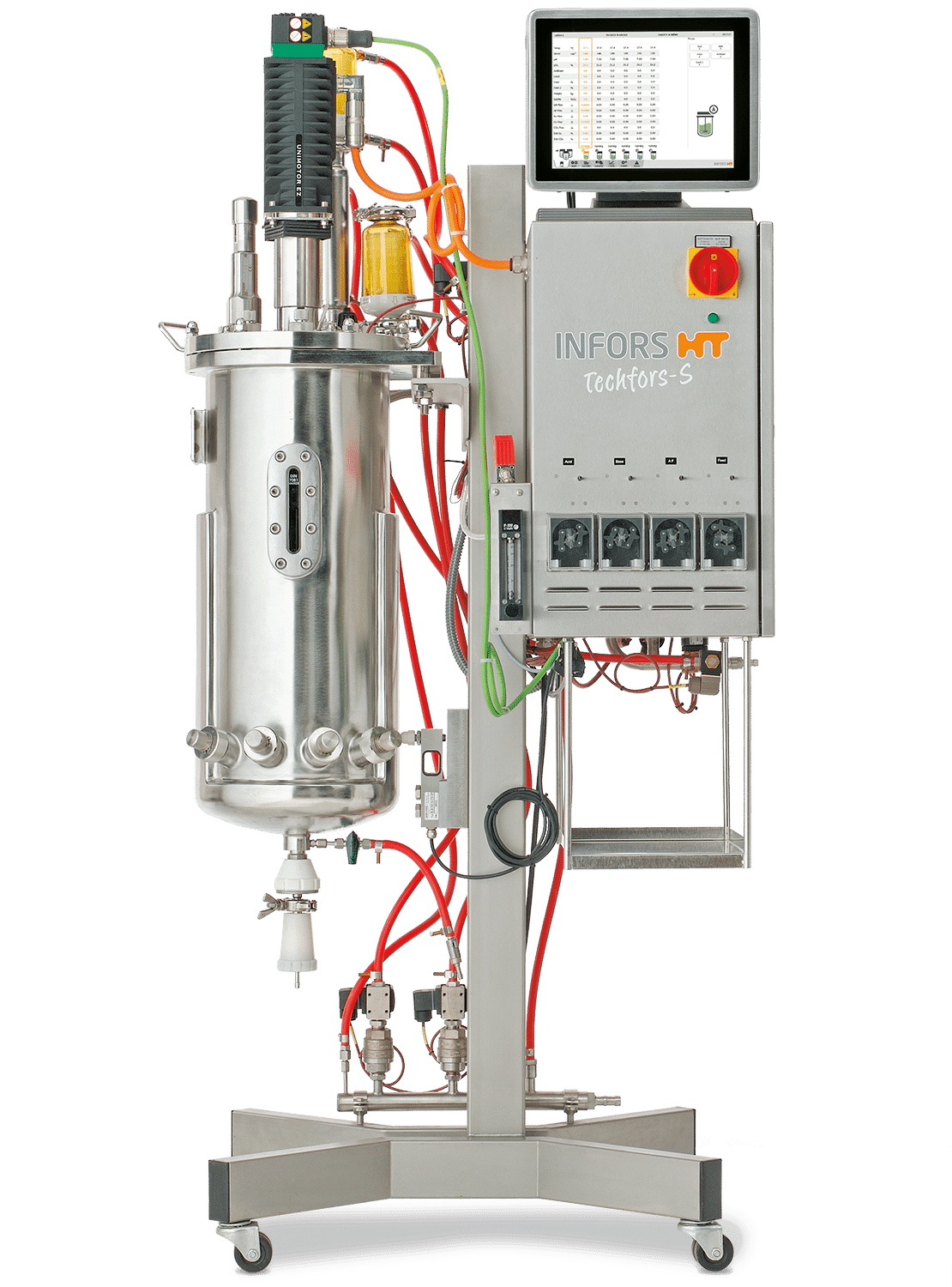

| Vessels | 1,5 L / 3 L / 6 L |

|---|---|

| Working volume | 0,3–1,0 L / 0,6–2,0 L / 1,1–4,0 L |

| Dimensions (W x D x H) | 455 mm x 375 mm x 740 mm |

| Drive | Version for Microorganisms: 150 min-1 to 1600 min-1 Version for cell cultures: 24 min–1 to 600 min-1 |

| Temperature | Coolant temperature + 10 °C bis 60 °C |

| Gassing per vessel | Version for microorganisms: 2 MFCs up to 2 min-1 Version for cell cultures: 5 MFCs up to 0.15 min-1 |

| Pumps per vessel | 4 x configurable (fixed or variable speed) ex-works: 3 x fixed (acid, base, anti-foam), 1 x variable (feed) |

| Pump performance | 0,0034 to 3,52 mL min-1 (standard), 0,017 to 16,13 mL min-1, 0,0012 to 1,12 mL min-1 |

| Ports per vessel | 7,5 mm 4x |

| Connectivity | OPC UA via Ethernet |

| Parallel operation via touch screen controller | n/a |

| Sterilisation | Autoclave |

Flyer & Brochures

Practical Advice

Thank you for your interest!

Please enter your e-mail address in order to download the document.

Application Notes

Manuals

Thank you for your interest!

Please enter your e-mail address in order to download the document.

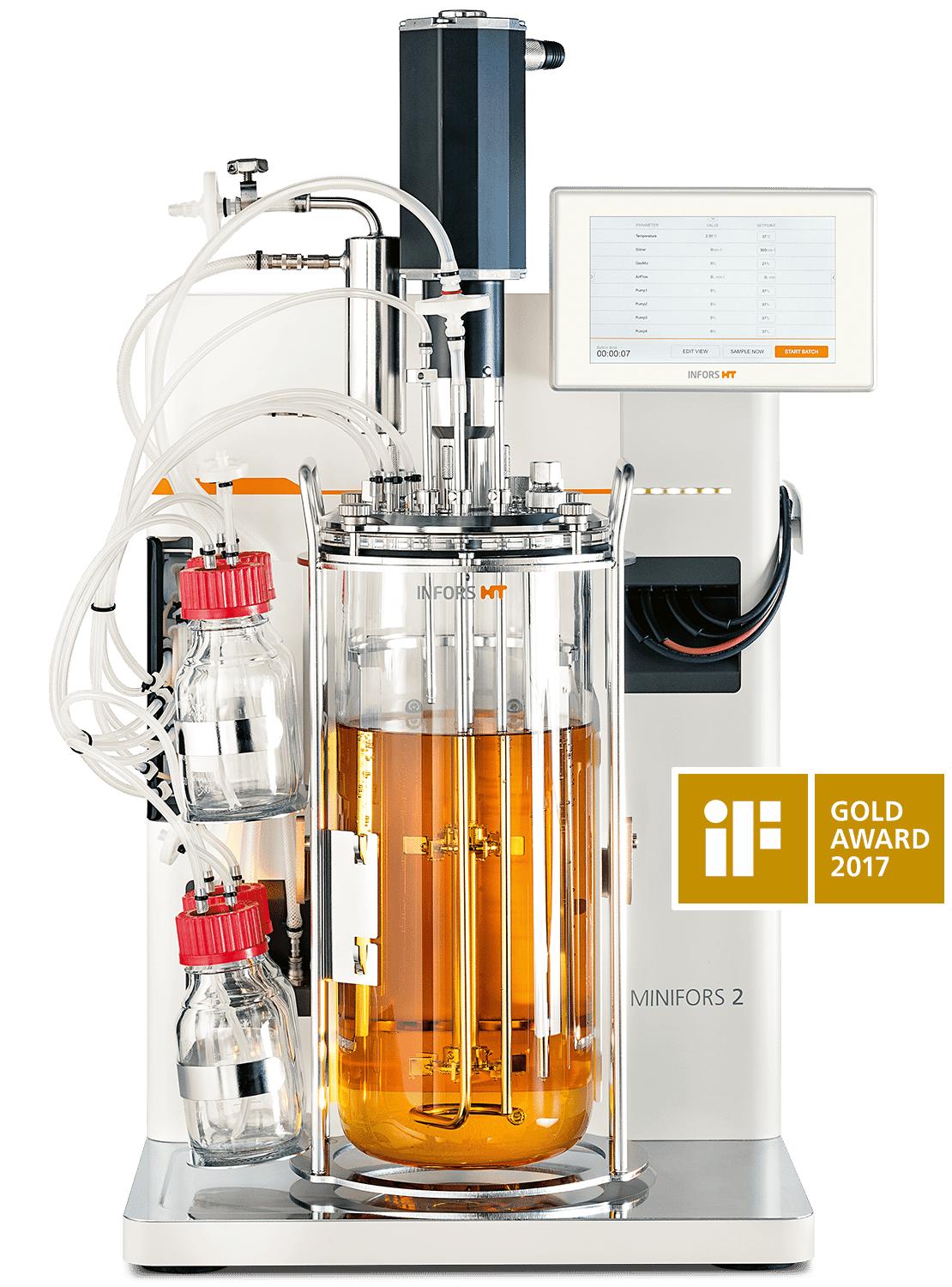

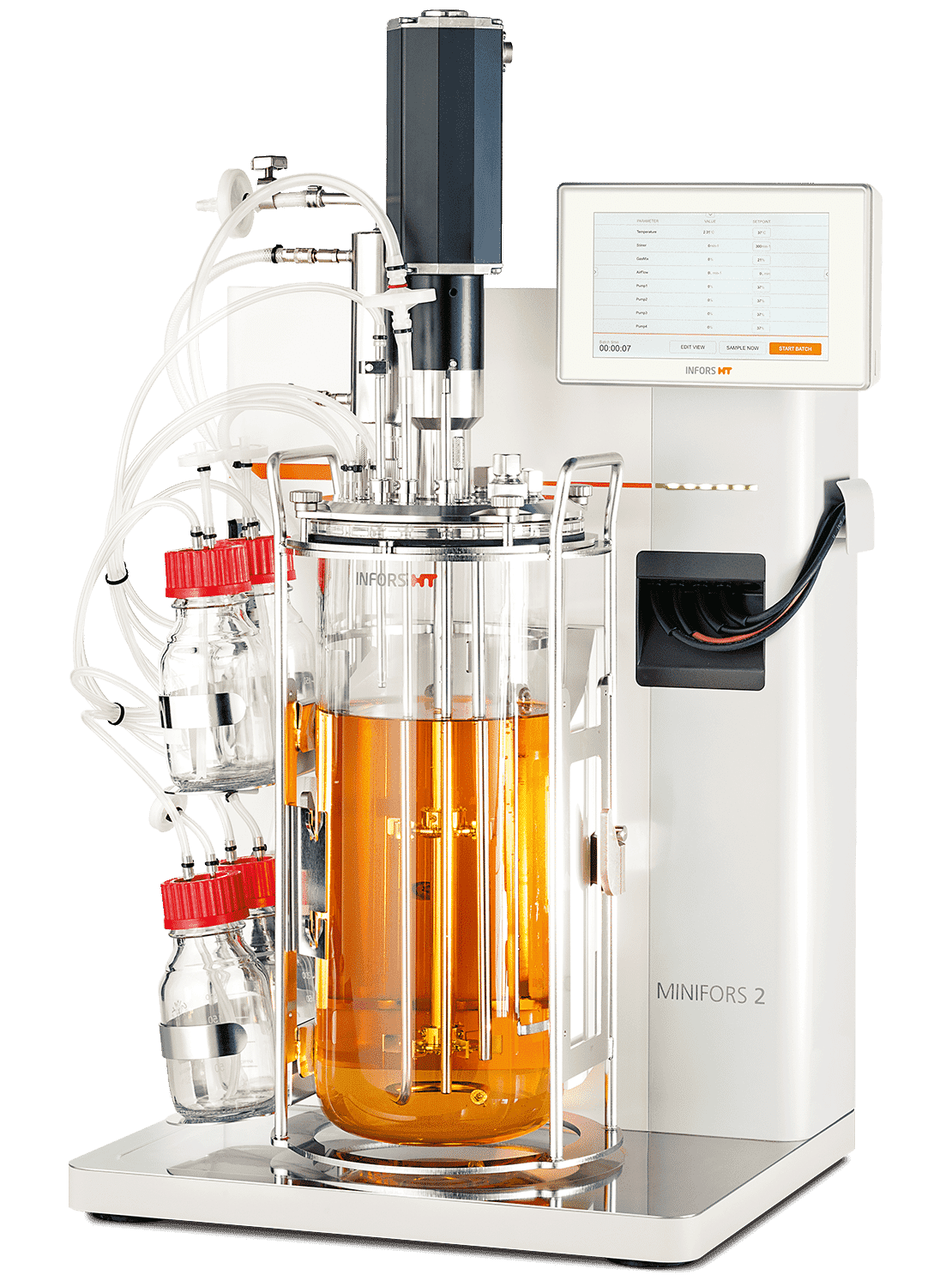

| Minifors 2 for Pichia pastoris | |||

|---|---|---|---|

| Vessels | 1,5 L / 3 L / 6 L | ||

| Working volume | 0,3–1,0 L / 0,6–2,0 L / 1,1–4,0 L | ||

| Dimensions (W x D x H) | 455 mm x 375 mm x 740 mm | ||

| Drive | Version for Microorganisms: 150 min-1 to 1600 min-1 Version for cell cultures: 24 min–1 to 600 min-1 | ||

| Temperature | Coolant temperature + 10 °C bis 60 °C | ||

| Gassing per vessel | Version for microorganisms: 2 MFCs up to 2 min-1 Version for cell cultures: 5 MFCs up to 0.15 min-1 | ||

| Pumps per vessel | 4 x configurable (fixed or variable speed) ex-works: 3 x fixed (acid, base, anti-foam), 1 x variable (feed) | ||

| Pump performance | 0,0034 to 3,52 mL min-1 (standard), 0,017 to 16,13 mL min-1, 0,0012 to 1,12 mL min-1 | ||

| Ports per vessel | 7,5 mm 4x | ||

| Connectivity | OPC UA via Ethernet | ||

| Parallel operation via touch screen controller | n/a | ||

| Sterilisation | Autoclave | ||